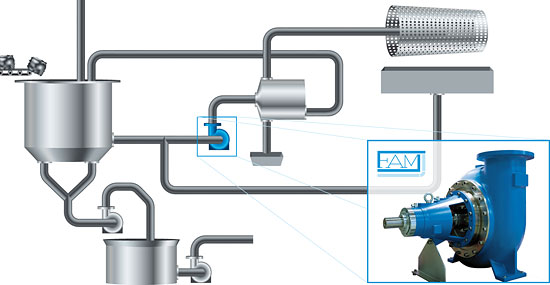

Cast-steel reject pumps

The main area of use is in pulping processes in paper- and cardboard-manufacturing plants that employ waste paper as a raw material. The FAM reject pump is installed between the pulper and the contaminant-separating machine. It supplies pumped material with absolute reliability, even in the presence of coarse impurities.

The FAM reject pump can also be used as a processed-material drainage pump.

- Pump housing made of cast stainless steel with flow-optimised design

- Specially-developed pump rotor

- Bearing support with stuffing-box housing, rotor and wearing wall in push-in configuration

- All bearings configured as roller bearings

- Replaceable wearing wall with protruding deflection ribs

- Divided, self-centring stuffing-box stay

Technical specifications:

| Weight without pulley | 970 kg |

| Connection flange at inlet | NW 400 |

| Connection flange at outlet | NW 350 |

| All individual components in wet zone |

Stainless steel |

| Pump-housing material | Cast steel 1.4408 |

| Pump-housing wall thickness | 20 mm |

| Pump-rotor material | Cast steel CB7Cu-1 |

| Wearing wall / deflection ribs | Cast steel CB7Cu-1 |

| Roller bearings | Cylinder-type and tapered roller bearings |

| Pump shaft | Pre-hardened rolled steel 1.7220 |

| Roller-bearing lubrication | Grease lubrication, oil-immersion lubrication possible |

| Power requirement | Between 20 and 40 kW |

© FAM INGENIERIA • Legal details